Inodyiwa Oiri Yekuchenesa Maitiro: Mvura Degumming

Product Description

Degumming process mumafuta ekunatsa chirimwa ndeyekubvisa gum tsvina muoiri isina kukora nenzira dzemuviri kana dzemakemikari, uye ndiyo nhanho yekutanga mukunatsa / kucheneswa kwemafuta. Mushure mekudzvanya nekudzvanya zvinonyungudutsa kubva mumbeu dzeoiri, mafuta asina kuchena anonyanya kuve ane triglycerides uye mashoma asiri-triglyceride. Iyo isiri-triglyceride yakagadzirwa inosanganisira phospholipids, mapuroteni, phlegmatic uye shuga yaizoita ne triglycerides kuti iite colloid, iyo inozivikanwa sehusina tsvina.

Iyo gum tsvina haingokanganisa kugadzikana kweoiri chete asi zvakare inokanganisa maitiro ekunatsa mafuta uye kudzika kwakadzika. Semuenzaniso, mafuta asina-degummed ari nyore kugadzira mafuta emulsified mukugadzirisa alkaline, nokudaro kuwedzera kuoma kwekushanda, kurasikirwa kwekuchenesa mafuta, uye kushandiswa kwezvinhu zvekubatsira; mu decolorization process, isina-degummed oiri inowedzera kushandiswa kweadsorbent uye kuderedza discoloring kushanda. Naizvozvo, kubvisa chingamu kwakakosha sedanho rekutanga mukunatsa oiri isati yapera mafuta, decolorization, uye kunhuhwirira kwemafuta.

Iyo chaiyo nzira dze degumming dzinosanganisira hydrated degumming (mvura degumming), acid kunatsa degumming, alkali yekunatsa nzira, adsorption nzira, electropolymerization uye thermal polymerization nzira. Mukugadzirisa mafuta anodyiwa, nzira inonyanya kushandiswa ndeye hydrated degumming, iyo inogona kubvisa hydratable phospholipids uye mamwe asiri-hydrate phospholipids, asi iyo yakasara isiri-hydrate phospholipids inoda kubviswa ne acid refining degumming.

1. Kushanda musimboti we hydrated degumming (mvura degumming)

Oiri isina kuchena kubva mukunyungudutsa yekubvisa ine mvura inonyungudika zvinhu, zvakanyanya zvinosanganisira phospholipids, iyo inoda kubviswa muoiri kuti igone kunaya zvishoma uye kugadzirisa panguva yekutakura mafuta uye kuchengetedza kwenguva refu. Iyo gum tsvina yakaita se phospholipids ine hunhu hwe hydrophilic. Chekutanga pane zvese, iwe unogona kumhanyisa uye kuwedzera imwe huwandu hwemvura inopisa kana electrolyte aqueous solution semunyu & phosphoric acid kune inopisa mafuta asina kuchena. Mushure meimwe nguva yekuita, kusvibiswa kwegum kwaizogadziriswa, kuderedzwa uye kubviswa kubva mumafuta. Muiyo hydrated degumming process, iyo tsvina inonyanya phospholipid, pamwe nemapuroteni mashoma, glyceryl diglyceride, uye mucilage. Zvakare, mazamu akabviswa anogona kugadziriswa kuita lecithin yechikafu, chikafu chemhuka kana kushandiswa kwehunyanzvi.

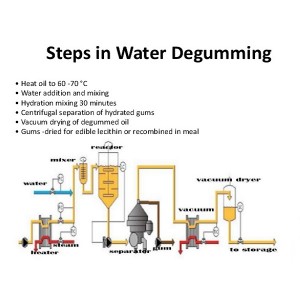

2. Maitiro ekuita hydrated degumming (water degumming)

Iyo mvura degumming process inosanganisira kuwedzera mvura kumafuta asina kuchena, hydrating mvura inonyungudika zvinhu, uyezve kubvisa mazhinji acho kuburikidza nekuparadzaniswa kwecentrifugal. Chikamu chechiedza mushure mekuparadzaniswa kwecentrifugal ndiyo mafuta asina kuchena, uye chikamu chinorema mushure mekuparadzaniswa kwecentrifugal musanganiswa wemvura, zvinhu zvinonyungudika nemvura uye mafuta akaiswa, pamwe chete anonzi "gums". Mafuta asina kuomeswa anoomeswa uye otonhodzwa asati aendeswa kunochengeterwa. Mazamu anodhonzerwa pakudya.

Muchigadzirwa chekuchenesa oiri, muchina we hydrated degumming unogona kushandiswa pamwe chete neoiri deacidification muchina, decolorization muchina, uye deodorizing muchina, uye michina iyi ndiyo inoumba mutsara wekugadzira oiri yekuchenesa. Mutsetse wekuchenesa unoiswa mumhando yepakati, semi-inoenderera mhando, uye yakazara inoenderera mhando. Mutengi anogona kusarudza mhando zvichienderana neavanoda kugadzirwa kwesimba: fekitori ine simba rekugadzira 1-10t pazuva rakakodzera kushandisa inopindirana mhando michina, 20-50t pazuva fekitori yakakodzera kushandisa semi-inoenderera mhando michina, kugadzira. anopfuura 50t pazuva akakodzera kushandisa zvizere kuenderera mhando michina. Mhando inonyanya kushandiswa ndeye intermittent hydrated degumming mutsara wekugadzira.

Technical Parameter

Zvinhu zvikuru zveHydrated degumming (water degumming)

3.1 Kuwanda kwemvura yakawedzerwa

(1) Mhedzisiro yemvura yakawedzerwa pa flocculation: Mvura yakakwana inogona kuumba yakagadzikana yakawanda-layer liposome chimiro. Mvura isina kukwana inotungamira kune isina kukwana hydration uye yakaipa colloidal flocculation; Mvura yakawandisa inowanzoita mvura-mafuta emulsification, iyo yakaoma kuparadzanisa tsvina kubva kumafuta.

(2) Hukama pakati pekuwedzera mvura yemukati (W) uye glum yemukati (G) mune akasiyana tembiricha yekushandisa:

| yakadzika tembiricha hydration (20 ~ 30 ℃) | W=(0)5~1)G |

| yepakati tembiricha hydration (60 ~ 65 ℃) | W=(2~3)G |

| yakanyanya tembiricha hydration (85 ~ 95 ℃) | W=(3~3.5)G |

(3) Sample test: Yakakodzera huwandu hwemvura yakawedzerwa inogona kutsanangurwa kuburikidza nemuenzaniso bvunzo.

3.2 Kushanda tembiricha

Tembiricha yekuvhiya inowanzoenderana neiyo tembiricha yakakosha (yekuyerera zvirinani, tembiricha yekushanda inogona kukwira zvishoma pane tembiricha yakakosha). Uye tembiricha yekushanda ichakanganisa huwandu hwemvura yakawedzerwa kana kutonhora kwakakwira, huwandu hwemvura hwakakura, kana zvisina kudaro, idiki.

3.3 Kusimba kwe hydration kusanganisa uye kuita nguva

(1) Inhomogeneous hydration: Gum flocculation ndeye heterogeneous reaction pane yekudyidzana interface. Kuti uite mhepo yakagadzikana yemafuta-mvura emulsion state, mechanical kusanganisa musanganiswa unogona kuita kuti madonhwe akapararira zvakakwana, kusanganiswa kwemagetsi kunoda kusimbiswa kunyanya kana kuwanda kwemvura yakawedzerwa yakakura uye kutonhora kwakaderera.

(2) Intensityof hydration mixing: Paunenge uchisanganisa mafuta nemvura, iyo inofambisa kukurumidza ndeye 60 r / min. Panguva ye flocculation inogadzira, iyo inomhanyisa kumhanya ndeye 30 r/min. Iyo yekupindura nguva yekusanganiswa kwe hydration inenge maminitsi makumi matatu.

3.4 Electrolytes

(1) Mhando dze electrolytes: Munyu, alum, sodium silicate, phosphoric acid, citric acid uye dilute sodium hydroxide mhinduro.

(2) Basa guru re electrolyte:

a. Electrolytes inogona kuderedza mamwe magetsi emagetsi e-colloidal particles uye kusimudzira iyo colloidal particles kuita sedimentate.

b. Kushandura iyo isiri-hydrated phospholipids kuita hydrated phospholipids.

c. Alum: flocculant rubatsiro. Alum inogona kutora pigments mumafuta.

d. Kuti chelate nesimbi ions uye kuvabvisa.

e. Kusimudzira iyo colloidal flocculation padhuze uye kuderedza mafuta emukati maflocs.

3.5 Zvimwe zvinhu

(1) Kufanana kwemafuta: Pamberi pemvura, mafuta asina kuchena anofanirwa kubvongodzwa zvakakwana kuitira kuti colloid igovane zvakaenzana.

(2) tembiricha yemvura yakawedzerwa: Kana ichiiswa mvura, tembiricha yekuwedzera mvura inofanira kuenzana kana kukwira zvishoma pane tembiricha yemafuta.

(3) Yakawedzerwa kunaka kwemvura

(4) Kugadzikana kwekushanda

Kazhinji kutaura, tekinoroji ma parameter e degumming process inotarwa zvichienderana nemhando yeoiri, uye ma paramita emafuta akasiyana mukuita degumming akasiyana. Kana iwe uchifarira kuchenesa mafuta, ndapota taura nesu nemibvunzo yako kana mazano. Isu ticharonga mainjiniya edu ehunyanzvi kugadzirisa mutsara weoiri wakakodzera uyo wakashongedzerwa neanoenderana neoiri yekuchenesa michina iwe.